Heavy-duty paint line

Developed to ensure durability and quality of finish for one of the most demanding multinational companies on the market.

AGCO

Challenge

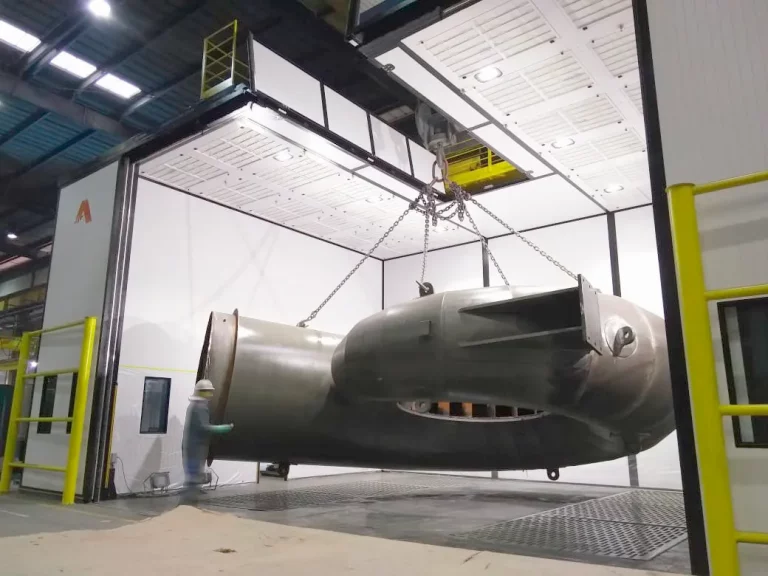

AGCO has been a recurring client of ours for over 5 years, and to maintain the quality and productivity of its painting process, it approached us to handle the expansion project of the painting sector at its branch in Mogi das Cruzes/SP. In addition to adhering to safety and ergonomic guidelines, as well as the network's quality standards, this project required the development of a handling system capable of transporting spray arms weighing up to 2 tons.

What was done

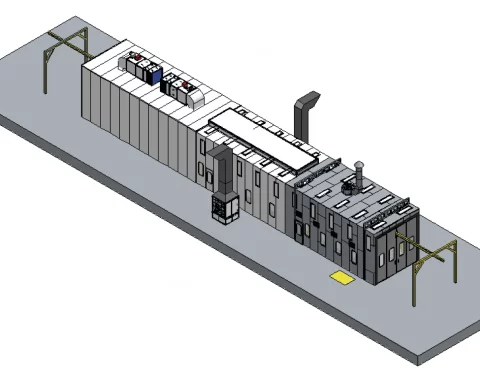

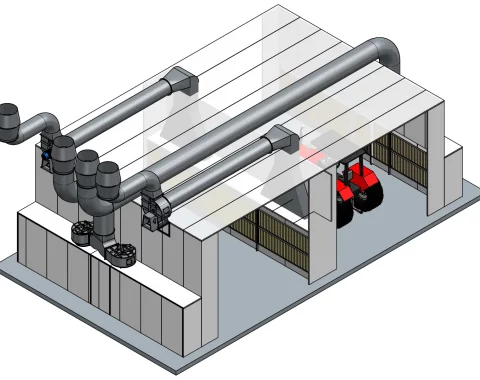

With the requirements in mind, we developed a paint line comprising a 3-in-1 pre-treatment sector for degreasing, defatting, and phosphating the parts. Following this stage is the paint booth, with a negative pressure system and down-draft airflow that directs the paint particles to the filtration system. Finally, there is a drying oven for curing the parts. The total length of the line is over 45m, and the parts are conveyed throughout this process via an overhead handling system that supports up to 2 tons.

Products used in this case

Check out more Case Studies

Expansion and high performance in painting High performance painting solutions: expansion…

Stationary booth for protective painting Robustness, quality and adaptability to improve the process…

Pressurized paint booth for touch-up Pressurized booth designed to meet the most demanding…

Designed to increase productivity while ensuring the high level of quality required by…