Drying ovens can be a game-changer for companies that need industrial-scale painting, or even automotive paint shops that want to increase productivity. Below, we'll learn what a drying oven is, how it works, and its benefits.

What are drying ovens?

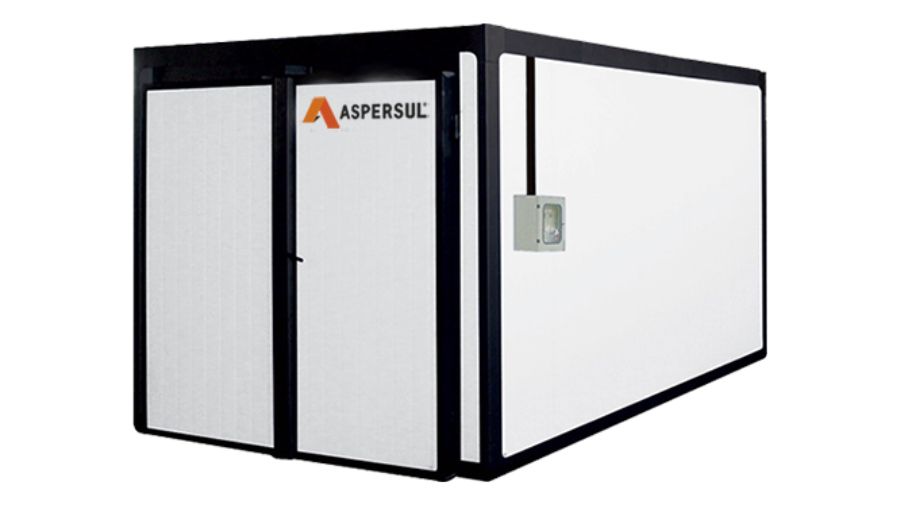

To the drying ovens These are structures designed to speed up part curing time, thus increasing line productivity. They can vary in size, fuel consumption, and other characteristics, depending on their use.

They're most often found in companies that pretreat and paint parts on an industrial scale, making them essential for reducing drying time after these processes. However, they can also be found in automotive paint shops and carpentry shops, for example.

Depending on their type of use, drying ovens can be divided into two basic types: continuous line and chamber.

Continuous ovens or passage tunnels are tailor-made for each need, which varies according to the size of the piece, drying time and production.

Chamber kilns are standardized for a specific kiln size, usually for small parts, but can be made to fit the specific part size.

THE drying oven for painting, it can have different wall dimensions, shapes, heating methods (with electricity or natural gas), and its floors can also be adjusted for better process operation.

How drying ovens work

Drying ovens operate using a heating system that can be carried out using electrical resistance, gas, fuel, steam, infrared, air renewal or UV tunnel.

The structure consists of thermoacoustic panels made of powder-coated carbon steel sheet and filled with EPS, PIR, or rock wool, depending on the application and drying temperature. Gas extraction towers are also recommended for situations involving the generation of solvents or other flammable materials during the drying process.

Depending on the need, it is possible to make models with access doors.

What are the benefits of drying ovens?

Obviously, the biggest benefit of a drying oven is the reduction in curing time, which allows for increased line productivity, but this is just one of the benefits.

Another important point is that temperature and drying time can be controlled using the electrical panel on the outside of the greenhouse.

Speaking of finishing, drying ovens have a system for filtering and exhausting contaminated air. This prevents dust particles and other dirt from coming into contact with the painted surface during drying, ensuring the desired high-quality finish.

Because they come in a variety of models and can be created to meet different size and production needs, the drying oven is a great option for those looking to increase their productivity and finishing quality.

To learn more about painting equipment and other industrial painting materials, visit the rest of our blog, always with new and exclusive content.