When we talk about industrial painting, it's impossible not to mention the variety of application systems. Depending on the type of material and the amount of paint used, it's necessary to select the application system that will deliver the best performance, both in terms of cost-effectiveness, transfer rate, and finish quality. Considering industrial painting as the main scenario, we find several systems: Airspray, Airless, Airmix®, and Electrostatic Airmix®.

In this article, we'll introduce the characteristics of each system, listing their respective advantages and ideal applications. By better understanding the specifics of each technology, you'll be able to study your process and choose the one that best meets your needs.

Airspray

Airspray, also known as airbrushing or HVLP, is an application technique that uses compressed air as a carrier for paint application. The compressed air atomizes the paint (sprays it) and directs it to the desired area. The paint adheres to the part through impregnation, and the atomized paint particles bond together to form a film on the part.

In this system, the transfer rate (amount of product applied to the part) varies between 40% and 65%. It is widely used for jobs that do not require large quantities of product, such as occasional work in furniture painting, metalworking, and the automotive repair industry.

Airless

The "Airless" painting system is an application system that does not use compressed air to atomize the paint. In this system, the paint is pressurized and forced through a small nozzle, creating a high-pressure jet that sprays the paint directly onto the surface to be painted.

The Airless paint system has a rate of up to 60%, making it ideal for applications requiring generous coats of product. On the other hand, the Airless system has a lower finish quality, which leads to a rougher and more uneven texture in some situations.

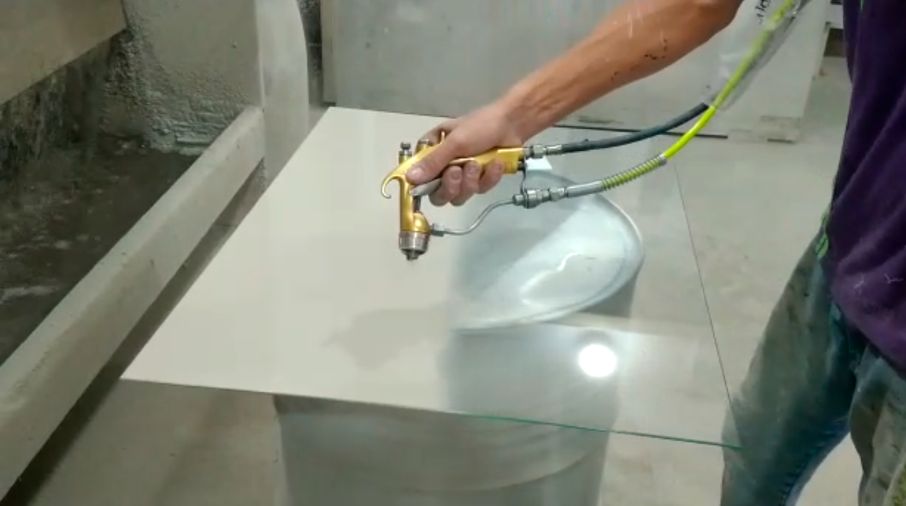

Airmix®

The Airmix® system is an improved combination of the Airless and Airspray systems, but incorporates a small amount of compressed air to aid paint atomization. In this system, the paint is still pressurized, but compressed air is also added to the gun nozzle, reducing paint mist and product consumption during applications.

This is one of the main technologies chosen by those seeking product savings, with high quality finishing, as it has a transfer rate of up to 86%, a percentage that is only lower than the Airmix® electrostatic application system.

Therefore, Airmix® proves to be a perfect alternative for jobs that require a high level of finish, such as painting furniture, doors, decorative pieces and projects that demand precise aesthetics.

Airmix® Electrostatics

The electrostatic system is widely used in large industries that value high transfer rates with minimal product loss and rework. This system utilizes electrostatic charging, where the grounded substrate receives the ink with a positive voltage, making application more efficient, with transfer rates exceeding 85%.

In the Airmix® electrostatic system for liquid paint, this rate rises to 90%, meaning it delivers much more product to the part, reducing product waste and rework.

But then, which system is more efficient?

It all depends on the requirements your paint line needs to meet, and often more than one type can be used for different needs within the industry.

If you're looking for spot applications and small corrections, the Airspray system is a good option. However, if your process requires thick paint coverage or uses paints with a high solids percentage, the Airless option will meet your needs.

However, if your line requires high productivity with a high standard of finishing and a reduced waste rate, using the Airmix® system is the best option.

To learn more about industrial painting and other content on painting and finishing, visit the rest of our blog, always with new and exclusive content.