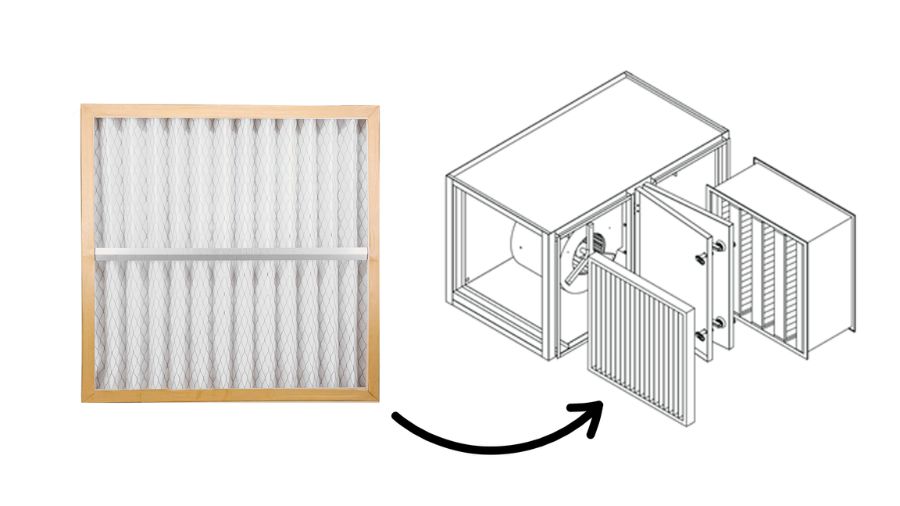

Also known as a sacrificial filter because it forms part of the first filtration barrier, the pleated cardboard filter is a type of filter used to remove particles and contaminants from the air. It consists of a cardboard frame and a pleated synthetic fiber filter media.

Its frame, also called cardboard, houses the synthetic fiber folded in a zig-zag pattern to form pleats, which increases the filter's filtering surface area and thus allows for greater particle retention capacity and air flow.

The pleated cardboard filter is commonly used in air conditioning, ventilation, air renewal systems, and paint booths and can be manufactured for classes G4 and M5. Let's learn a little more about this type of filter and how it works in a professional paint booth.

How a pleated cardboard filter works:

A pleated cardboard filter works by retaining particles and contaminants present in air or fluids as they pass through the filter media. The filtration process occurs as follows:

The air or fluid to be filtered is directed to the pleated cardboard filter, which is typically installed in a ventilation system at its first air inlet. The pleated cardboard's zigzag pattern creates a larger surface area than conventional flat filters, increasing particle retention capacity.

As air or fluid passes through the filter media, particles are trapped in the synthetic fibers of the pleated carton and the clean air or fluid is released into the environment or industrial process.

Over time, the filter media can become saturated with particles and contaminants, which can affect the filter's effectiveness. In this case, it needs to be replaced.

Importance of the pleated cardboard filter for the painting process

A pleated cardboard filter is very important to a paint booth system for several reasons:

Painting quality

Particles in the air can affect paint quality, causing defects such as stains and irregularities. The pleated cardboard filter traps these particles, helping to ensure a uniform, high-quality paint job.

Productivity

Airborne particles can accumulate on the surface of the painted object and reduce paint adhesion, necessitating rework and increasing production time. A pleated cardboard helps avoid these issues, reducing rework.

In other words, a pleated cardboard filter is extremely important, as it guarantees the quality of the painting and increases the efficiency of the process.

Benefits of a pleated card filter:

The pleated cardboard filter offers several benefits compared to the flat cardboard filter. Some of these benefits include:

Filtration system protection

The pleated carton creates a larger surface area than conventional flat filters, which increases particle retention capacity and improves filtration efficiency.

Less resistance to airflow

The pleated carton filter has lower airflow resistance than other types of filters, which helps reduce energy consumption and operating costs.

Great value for money

The pleated carton filter has a longer lifespan than conventional filters, which means they need to be replaced less often.

Greater particle retention capacity

This filter model has a greater particle retention capacity than the flat carton filter, especially when removing G4 and M5 particles and contaminants from air or other fluids.

To learn more about filters and how other essential components in a paint booth work, visit our blog, always with new and exclusive content.