A paint booth is a controlled environment where objects or vehicles are painted, and whose main purpose is to provide a location with controlled ventilation and filtration, ensuring that the paint is applied uniformly and safely, minimizing contamination by dust or particles.

Among its models, the main difference lies between dry-process and wet-process booths. But what is the difference between these two models, and which one should I choose for my company or painting project? We answer these and other questions below:

Unveiling the paint booths

Next, we will explain in more detail the main differences between dry and wet paint booths and how they can help ensure a controlled painting environment:

Dry paint booth

The air filtration process in a dry paint booth involves a series of steps. The first is air intake, where ambient air is drawn into the booth and filtered to remove dust particles. The first stage of filtration usually involves fiberglass or paper filters that capture larger paint particles; however, these filters are replaceable and need to be changed regularly.

Even during the painting process, excess paint is sprayed (oversprayThe air is captured by the airflow directed to the filters (negative pressure), a flow created by strategically positioned exhaust fans in the cabin's design. In this second filtration stage, using activated carbon filters, smaller particles and solvent vapors are captured, improving the quality of the air exiting the cabin.

The filtered air is then exhausted out of the cabin, often passing through a final filter to ensure that no particles harmful to the environment are released into the outside environment.

Advantages

Dry paint booths offer several advantages, one of the main ones being the lower investment cost, since dry booths generally have a lower initial cost compared to other models, as they do not require water recirculation and treatment systems.

The use of dry filters and simple exhaust systems also reduces the complexity and cost of the necessary equipment, making the entire maintenance process much simpler, especially those involving the periodic replacement of filters.

For these reasons, dry paint booths are ideal for workshops and companies with smaller production volumes; furthermore, they are easily adaptable to different sizes, allowing for greater flexibility in small operations.

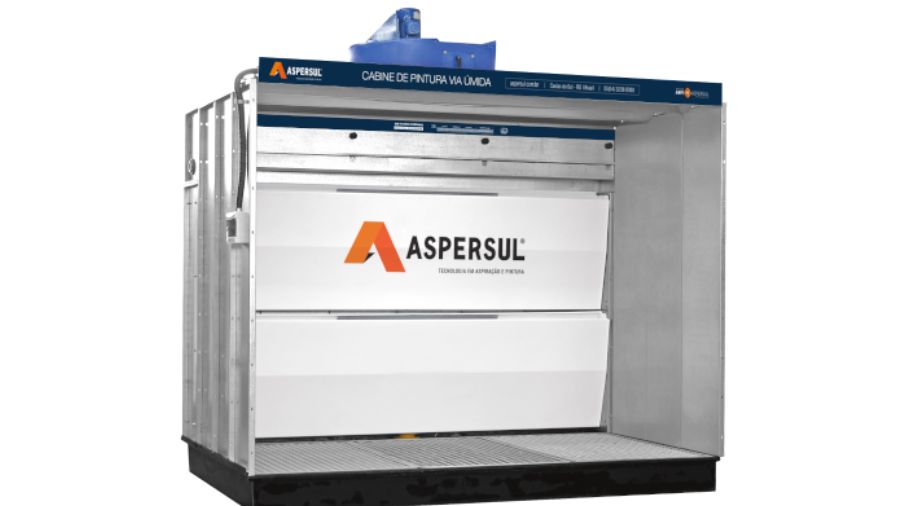

Wet paint booth

The key difference in a wet paint booth is the use of a water curtain filtration process through paint capture mechanisms and overspray.

The air intake into the cabin is very similar to the process in other models, with filters that prevent impurities from entering. However, during the painting process, a continuous stream of water is created at the rear of the painting area. The paint mist (or oversprayThe spray is drawn toward this curtain by the air current. When the paint mist comes into contact with the water curtain, the paint particles are captured and carried to a water collection tank located at the base of the booth.

The water containing these paint particles is recirculated through a filtration system to remove the paint, while fresh air, now free of paint particles, is exhausted from the booth through a ventilation system, passing through additional filters to ensure that no contaminants escape.

Advantages

Using water as a capture medium allows for even more effective retention of paint particles, resulting in less air pollution. Furthermore, this efficiency in capturing particles results in a cleaner and more uniform painted surface, providing a high-quality finish. Less contamination during the painting process means fewer defects, such as blemishes and roughness, reducing the need for rework.

Detailed comparison

Filtration efficiency

Dry paint booths use paper or fiberglass filters to capture paint particles, and although efficiency data varies, it is estimated that these filters capture between 70% and 90% of larger particles.

The use of a water curtain to capture paint particles is typically superior, around 95%, including fine particles which, due to the ability of water to absorb and retain these particles, can reach up to 99% of retention.

Quality of the finish

Despite the professional quality that can be achieved through the use of a dry paint booth, wet paint booths provide a superior finish thanks to their high particle capture efficiency, resulting in a more uniform and smooth surface with fewer visible imperfections, leading to less need for rework.

Cost-benefit

Dry paint booths offer a much lower initial investment, with lower installation costs and relatively simple filtration systems. Furthermore, they also have lower operating costs due to lower energy consumption and the absence of a water circulation system. This also impacts maintenance costs, which are simpler and cheaper, especially those related to periodic filter replacement.

While wet paint booths obviously have a higher initial cost due to the complexity of the recirculation and water treatment systems, as well as higher operating costs, mainly due to the water and energy consumption required to keep the system running, this type of booth is ideal for large-scale operations where the quality of the finish and the efficiency of the operation justify the investment.

Environmental impact

Despite their lower energy consumption, dry paint booths produce a significant amount of solid waste in the form of used filters, which need to be disposed of properly. Although they consume fewer resources, the increased generation of solid waste and atmospheric emissions can result in a considerable environmental impact, especially in larger-scale operations.

While wet paint booths consume more energy and water, they generate less solid waste because the water is used to capture paint particles, which can then be treated and recycled. Furthermore, their emissions are significantly reduced due to their high efficiency in capturing paint particles.

Decisive factors in the choice

Several factors can be decisive in choosing between a dry or wet cabin; let's look at the main ones.

Production volume

Dry-process booths are ideal for small-scale operations, such as automotive repair shops or small manufacturers. Dry-process booths may also be sufficient for operations where extreme quality is not critical, while wet-process booths may be justified if finish quality and particle capture efficiency are priorities, making them ideal for large manufacturers, such as automotive and heavy equipment industries, where production is continuous and on a large scale.

Desired finish

For finishes where aesthetic quality is important but not critical, both booths can meet the needs, although the wet booth offers an advantage in terms of uniformity, but the ability to capture particles and reduce visual defects makes the wet booth essential for high-quality finishes.

Costs and budget

Due to their lower operating costs, reduced energy consumption, lack of water treatment requirements, and lower initial costs due to the simplicity of their filtration and ventilation systems, dry paint booths are suitable for operations with limited budgets or where high-quality finishes are not critical. Wet paint booths, on the other hand, are justified for operations where high-quality finishes and efficient particle capture are essential, resulting in long-term savings through reduced rework and environmental compliance.

When making the decision, it is crucial to consider not only the immediate costs, but also the long-term impact in terms of quality, safety, and environmental impact. Assessing the total life cycle of the cabins and their associated benefits can help determine the most economical and efficient option for your specific needs.

THE Aspersul We offer a wide variety of booth models, both dry and wet, to meet your needs for maximum quality in painting and vacuuming. Visit our website and discover the perfect paint booth solution, or speak with one of our representatives – through our various contact methods – to help you choose the perfect paint booth for your company.

Did you like this post? Share it with your friends or on social media. For more tips on painting and its equipment, visit our blog, always with exclusive content.