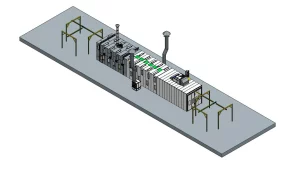

With advanced temperature control, thermal insulation, and robust construction, drying ovens can handle a wide range of processes, making them a solution for any operation seeking excellence and efficiency. They are essential for ensuring uniform curing, resistance, and a flawless finish in electrostatic painting, from small parts to large metal structures. With precise thermal control and optimized airflow, they provide high productivity and energy efficiency, meeting the diverse demands of the industrial sector.

Benefits

Homogeneous heating – Uniform heat distribution for better paint curing quality.

Energy efficiency – Advanced thermal insulation that reduces energy consumption.

Robust construction – Materials resistant to high temperatures and corrosion, ensuring durability.

Modular models – They allow adaptation according to the available space and production needs.

Available Models

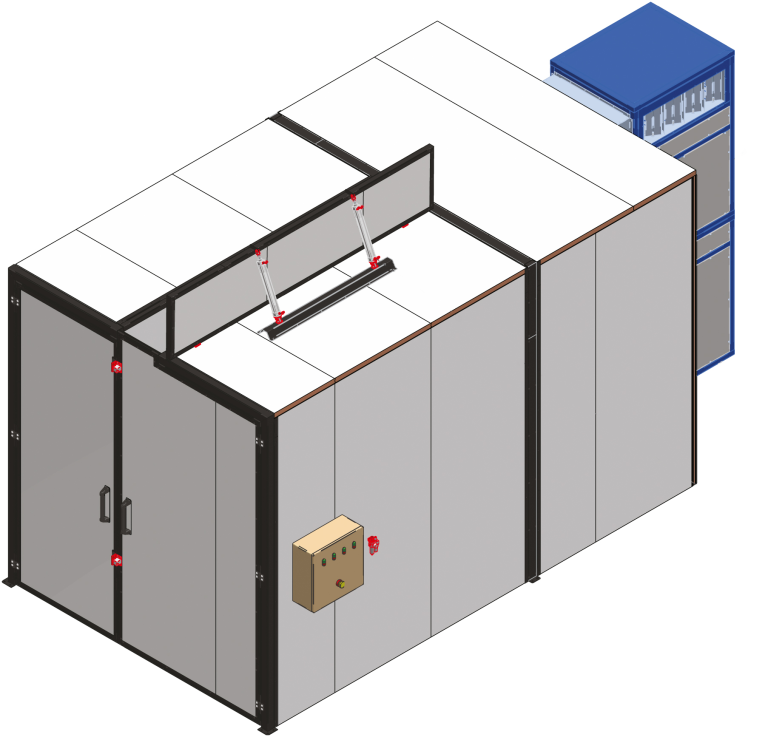

- Conventional Greenhouse

For standard electrostatic painting processes, the Conventional Oven stands out for its efficient thermal control, achieved through forced air circulation, thermal panels and digital temperature control, ensuring reliable and consistent results.

Available Sizes: 3m x 2m | 5m x 3m | 8m x 4m.

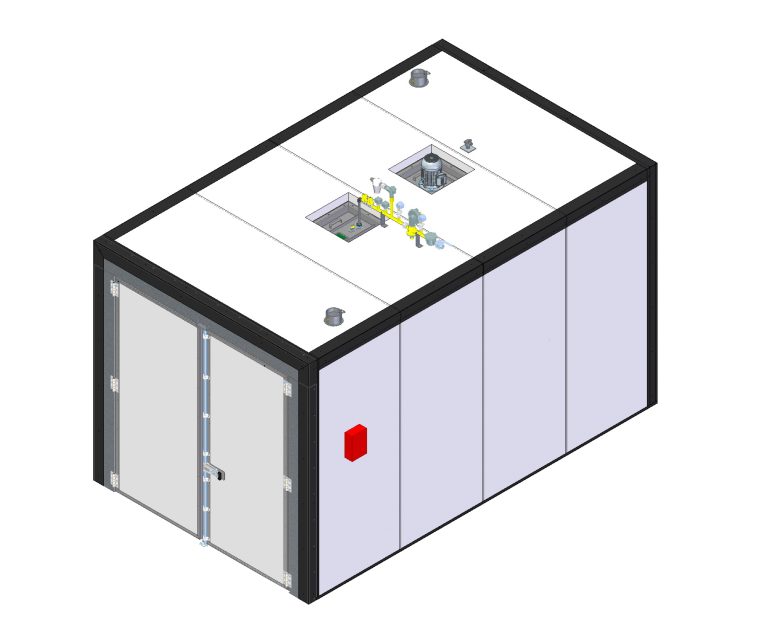

- High Performance Greenhouse

For intensive processes that require reduced curing time and greater thermal control, the High Performance Oven uses electric or gas heating, reinforced insulation and distributed sensors, ensuring maximum precision and efficiency in paint curing.

Available Sizes: 6m x 3m | 8m x 4m. For custom sizes, please contact our team.

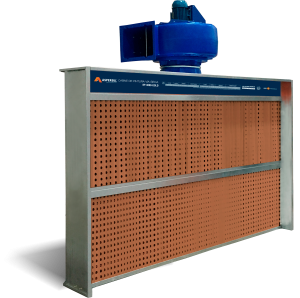

- Greenhouse with Energy Recovery

Suitable for operations that prioritize energy efficiency and lower operating costs, the Energy Recovery Oven uses residual heat, features advanced digital control, and has an optimized thermal structure, reducing consumption and increasing performance.

Available Sizes: 5m x 3m, 7m x 4m, modular customization.