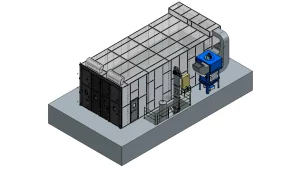

The AP Booth was developed for companies that operate two or three painting shifts, work with UV or high-solid paints, and require an efficient system without long maintenance downtimes. Its high-capacity filtration capacity allows it to handle large particle loads, ensuring a controlled and productive painting environment.

The key differentiator of this model is its easily accessible tank, which allows maintenance without interrupting operations. During use, the application of coagulants and flocculants separates the paint sludge from the water and collects it directly in the side tank, allowing residue removal while the booth is still running. This drastically reduces maintenance downtime, optimizing production flow.

Furthermore, the filtration system with deflectors and backwash increases the efficiency of overspray capture, ensuring a continuous process with lower operating costs.

Technical Characteristics

- Easy-access tank, allowing maintenance without interrupting operations

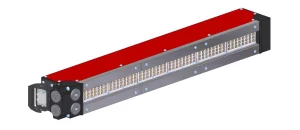

- Sistema de filtragem com defletores e retrolavagem, aumentando a eficiência na captação de resíduos

- Maior área filtrante no pulmão, reduzindo a saturação e a necessidade de limpezas frequentes

- Tanque com cortinas d’água horizontais, garantindo melhor captura do overspray

- Opção de tanque lateral para manutenções ou integração com estação de tratamento

Available Configurations

- With or without extended floor

- Com ou sem cortina lateral

- Com cortina dupla ou tripla

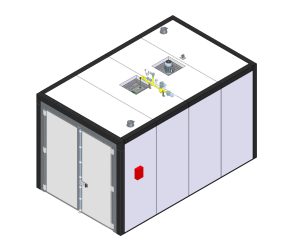

Available Dimensions

- 2080 x 2220 mm to 6080 x 2220 mm (WxH)