In a world where efficiency and sustainability are increasingly prioritized, exhaust filters play an essential role in various industrial processes, not only ensuring air quality but also contributing to reducing environmental impacts, protecting equipment and employees from harmful particles and substances.

Next, we will explore the main exhaust filter models available on the market, such as the inertial letter filter and the PA flat filter, each with specific characteristics and applications. Throughout this text, we will list the main factors to be considered, from the type of particle to be filtered to the air flow and system pressure, to choose the correct exhaust filter.

What are exhaust filters?

Exhaust filters are components designed to capture particles, pollutants and harmful substances released into the air by industrial, commercial and automotive ventilation and exhaust systems. Their main purpose is to retain solid and liquid particles, toxic gases and volatile compounds before they are released into the external environment, contributing to occupational and environmental safety.

Filters vary in technology and efficiency and can be composed of layers of synthetic fiber, activated carbon, glass fibers, metal meshes or even advanced technologies such as electrostatics.

Importance of filtration for air quality

Exhaust filters prevent dust, chemical vapors, and other pollutants from spreading throughout the work environment or being released into the atmosphere, ensuring cleaner air. Uncontrolled emissions of volatile organic compounds (VOCs), soot, and chemical residues can harm ecosystems and contribute to environmental problems and global warming. Filtering minimizes this impact.

Many industries are required to use exhaust filters to meet emission control standards, such as those established by environmental and regulatory agencies, as inhaling contaminant particles can cause respiratory problems, allergies, and more serious illnesses, such as chemical poisoning.

Exhaust filters significantly reduce these risks, and in industries and production processes, well-designed exhaust filters prevent the accumulation of dirt in equipment, extending its useful life and reducing the need for frequent maintenance.

Types of exhaust filters

Inertial chart filter

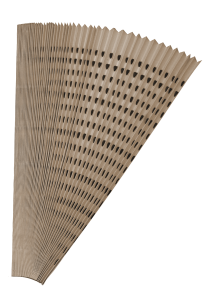

Made from high-strength kraft paper, ensuring durability and efficient particle capture, the inertial card filters have a double layer of corrugated cardboard, which creates a labyrinthine path for airflow, increasing contaminant retention.

Furthermore, they feature alternating holes that direct the air in a way that promotes efficient separation of particles, preventing them from returning to the environment and – because they are a lightweight and easy-to-install structure – they become one of the most economical filters for specific applications.

Its operation is relatively simple: air contaminated with paint particles and other residues enters the filter and is forced through alternating channels in the corrugated cardboard. This labyrinthine path causes the particles to collide with the filter walls, separating them from the airflow.

The retained particles accumulate inside the filter, while the clean air continues its journey, improving the quality of the environment and, as it does not use additional liquids or filter blankets, its efficiency depends on the structural design and the correct air flow.

These models are widely used in dry paint booths, where the capture of paint particles is essential to prevent environmental contamination and are recommended for industrial processes that do not involve toxic vapors or volatile compounds that require chemical filtration.

PA Flat Filter

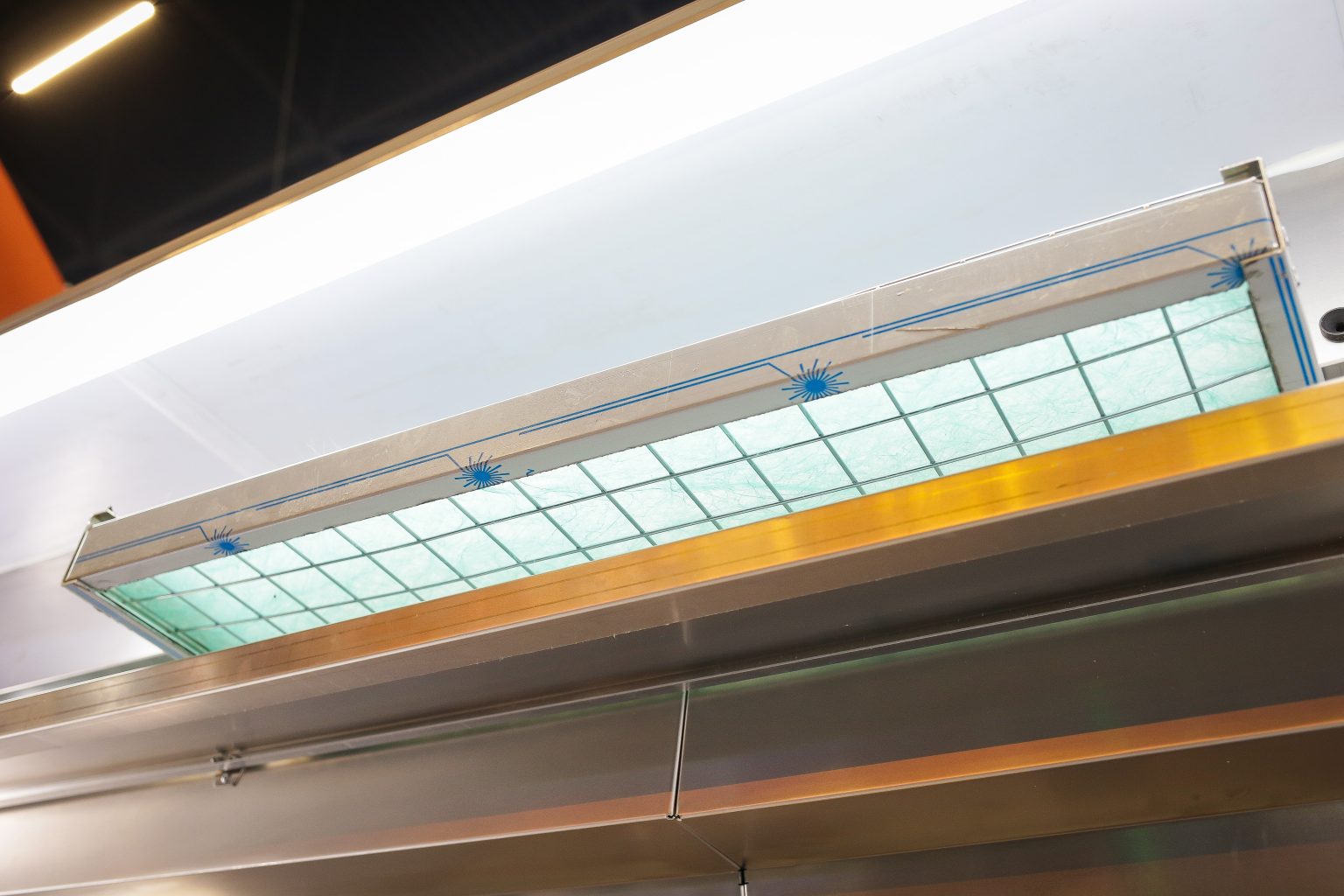

PA flat filters have a rigid cardboard frame, which gives the filter structure that facilitates its installation and replacement. In addition, they have internal metal screens, which guarantee greater resistance and stability to the filtering medium, preventing deformation under high air pressure.

These models are available with a variety of filter media, depending on your filtration needs, including: polyester (excellent retention of solid particles and long service life), fiberglass (ideal for capturing fine particles, such as paint mist and aerosols) and activated carbon (in addition to particle filtration, it helps absorb odors and volatile organic compounds).

PA flat filters are designed to withstand high air pressures, ensuring efficient filtration without compromising exhaust flow. This allows contaminated air to pass through the filter media, where paint mist particles and other suspended debris are retained. The metal screens help distribute air evenly throughout the filter, maximizing its efficiency and preventing rapid saturation points. Models with activated carbon also utilize a chemical adsorption process, which reduces odors and harmful vapors.

These filter models are widely used in paint mist filtration (overspray) in painting booths and present in industrial processes that require control of atmospheric emissions and improvement of air quality in the work environment.

Paint Stop PA 40 Filter

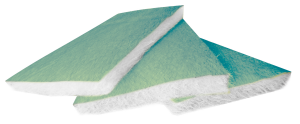

Composed of high-efficiency fiberglass, a material widely used in capturing airborne particles, it has a progressive structure, where the densest layers are at the air outlet, ensuring gradual particle retention and preventing premature clogging.

This model has excellent paint and aerosol retention capacity, preventing residues from being released into the external environment and is resistant to solvents and chemicals used in painting processes, extending its useful life.

Available in custom cuts to fit different types of equipment and exhaust systems, it is also supplied in rolls, allowing flexibility for custom cuts according to application needs. Furthermore, its malleability facilitates installation and periodic replacement, optimizing filtration system maintenance.

How to choose the ideal filter?

When choosing an exhaust filter, it's essential to consider several factors to ensure system efficiency and meet application needs. For example, consider the type of particle to be filtered: solid particles, such as dust, sawdust, and dried paint residue, require high-retention mechanical filters, such as Inertial Card Filters or PA-50 and PA-100 Filters. Liquid paint mists and aerosols require fiberglass filters, such as the Paint Stop PA 40 Filter, and volatile organic compounds (VOCs) and odors can be better filtered with filters containing activated carbon.

The chosen filter must also allow adequate air flow without compromising ventilation, as very dense filters can reduce airflow and require more power from the exhaust system. In this case, models like the PA Flat Filter are designed to withstand high airflows without losing efficiency.

Filters must also be able to operate under different pressure levels without compromising their structure. In applications with high particle volumes, filters with progressive layers help retain contaminants without quickly saturating. In paint booths, a staged filtration system (e.g., an Inertial Card Filter plus PA-50 or PA-100) provides superior performance.

To ensure you choose the most suitable filter, we recommend seeking specialized technical support. KORIA® professionals can assess the environmental conditions, application type, and regulatory requirements to recommend the best solution. Contact us at WhatsApp.

Did you like this post? Share it with your friends or on social media. For more tips on painting and its equipment, visit our blog, always with exclusive content.